It is too troublesome to change the water in the acrylic bending machine, what should I do?

Acrylic Bending Machine requires frequent water changes, which is too troublesome. What should we do?

It’s troublesome to always change the water in the acrylic hot bending machine!

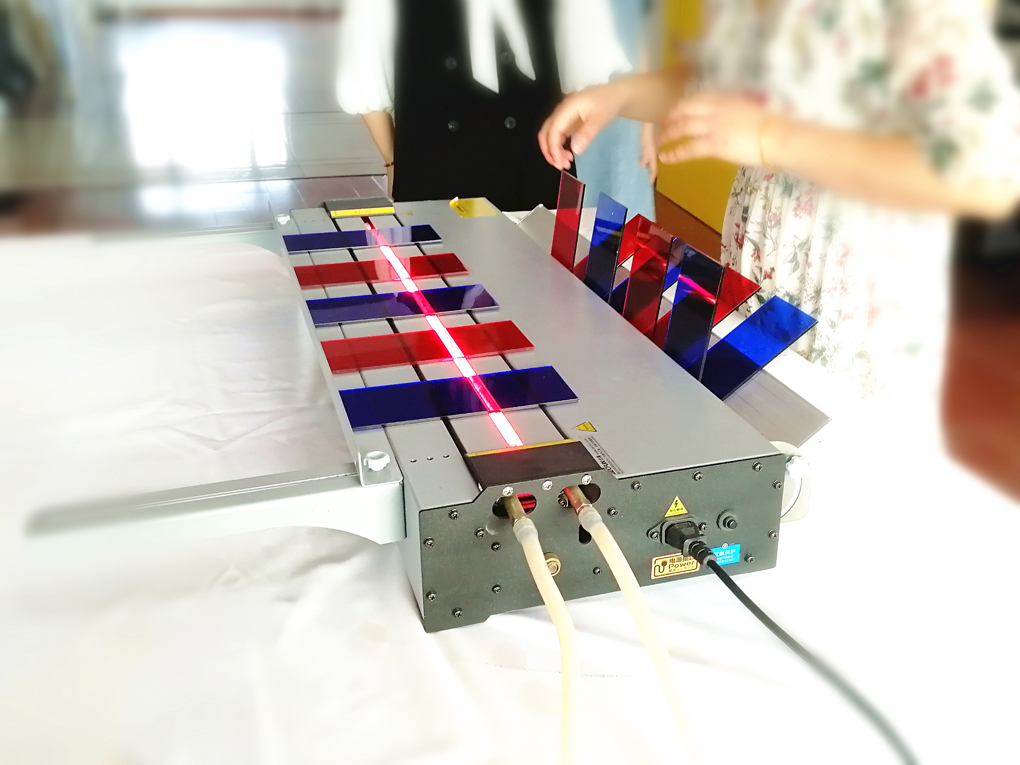

We have received feedback from many customers that acrylic sign orders are now busy, causing the hot bending machine to work for a long time, sometimes for 10 hours continuously, and then the circulating water gets hot very quickly. So it’s troublesome to always need to change the water. What should we do?

We have received feedback from many customers that acrylic sign orders are now busy, causing the hot bending machine to work for a long time, sometimes for 10 hours continuously, and then the circulating water gets hot very quickly. So it’s troublesome to always need to change the water. What should we do?

Don't be lazy. Using hot water circulation will not only affect the life of the equipment and water pump, but also affect the quality of plate processing. Based on the actual situation, we have some suggestions for your reference.

1: You need to prepare a larger water tank

What we recommend is to prepare a large turnover box to use as a water tank. It can hold more than 50L of water, and the larger the capacity, the better. Because the water tank is large enough and holds a lot of water, the water temperature rises slowly.

Some customers use kegs for convenience. A bucket will work too. But buckets have two disadvantages:

1) The bucket is small in size.

2) The opening of the bucket is small and the heat dissipation is not as fast as that of the turnover box.

2) The opening of the bucket is small and the heat dissipation is not as fast as that of the turnover box.

Some clients prepare two buckets and use them in turn, which is also a good idea. (When changing the water, be careful not to get water on the machine and the heating pipe, because the heating pipe will burst when exposed to cold water)

Therefore, we recommend using large turnover boxes. It is also easily available for factories.

You can also add some ice to the water.

2: You need to equip a dedicated chiller

The tank is open and exposed. In summer, sticky dirt is easily produced in the water, and the dust in the workshop often falls in. Although the water does not need to be changed frequently because of the high water temperature, the water tank must be cleaned regularly because of dirt. Some users still can’t accept it, what should we do?

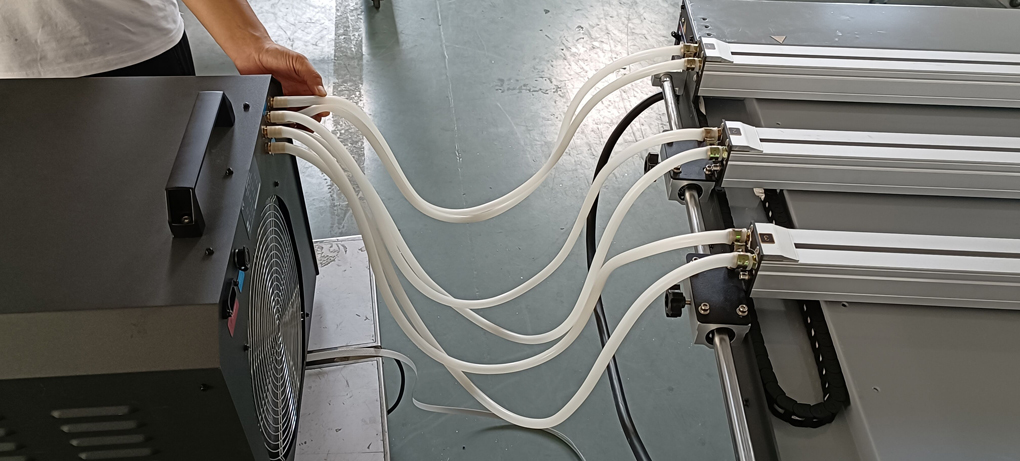

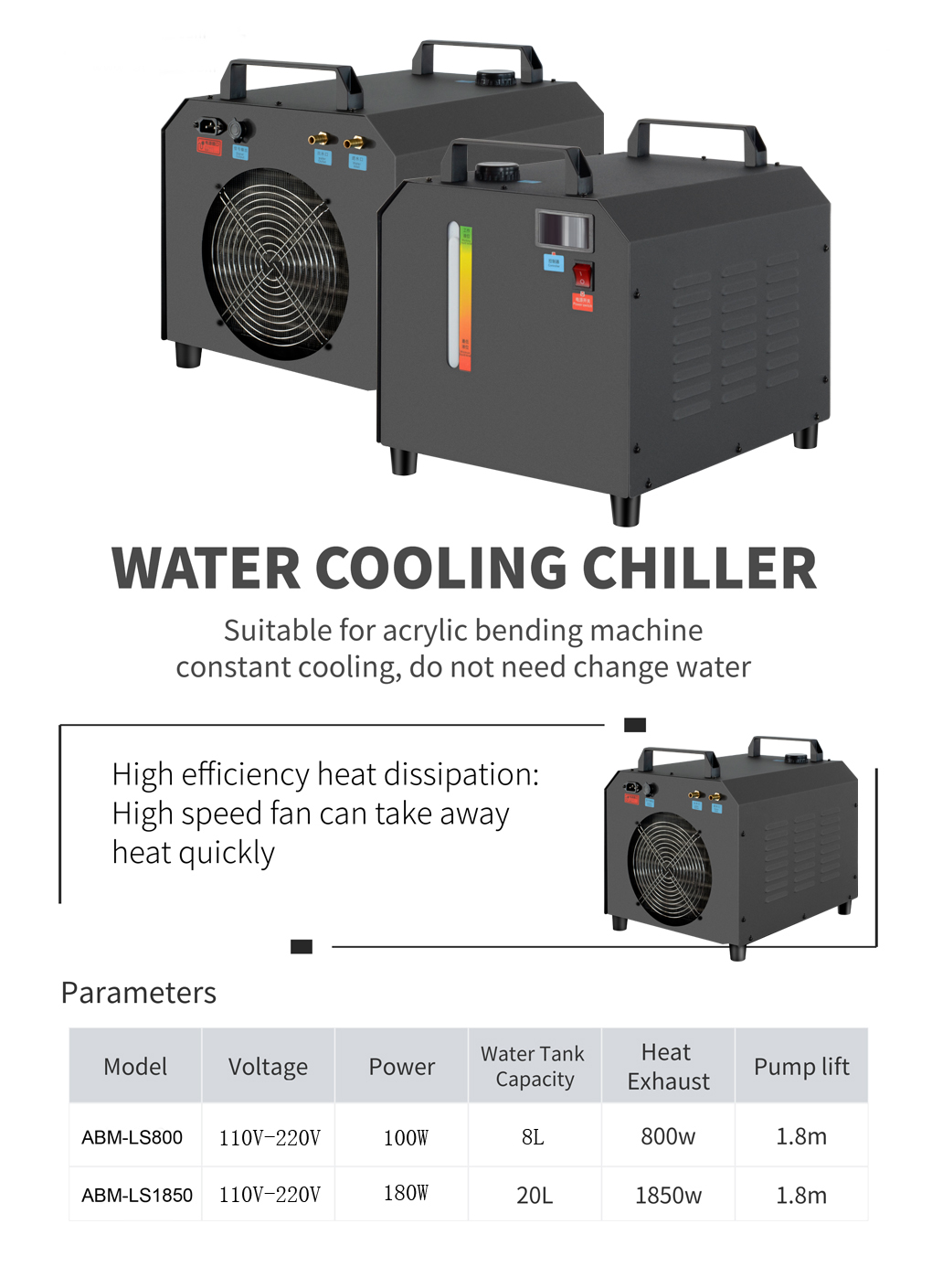

A water chiller can help you. We tested a small water-cooled machine ABM-LS800, suitable for 1.5KW bending machines; a larger water-cooled machine model ABM-LS1850, suitable for 4.5KW bending machines.

The video below is a test of a chiller. The power of the machine is about 4.5KW and it works for 8 hours. The temperature of the chiller is maintained at more than 30 degrees. It can be used for a long time and continuously cools down, solving the trouble of always changing water.

Related Products:

CALCA 800W Water Cooling Chiller for Acrylic Bending Machine, 110-220VAC

CALCA 1850W Water Cooling Chiller for Acrylic Bending Machine, 110-220VAC